I Innovation lies at the heart of our operations and business principles. By thinking outside the box, keeping pace with global standards of battery manufacturing, and leading from the front in delivering the best products to our customers, we are continuously engaged in research, learning, and capability development.

Our Research and Development Centre is located in the eastern part of India, in Kolkata. Established in 1976 under the leadership of several eminent scientists, the Centre has since gained recognition under the ‘Department of Science and Industrial Research (DSIR),’ Government of India.

The Eveready R&D Centre is fully equipped with a Chemical and Physical Laboratory, Cell Testing Facility, Pilot Plant, and various other state-of-the-art testing facilities to meet advanced requirements, enabling further improvement and troubleshooting.

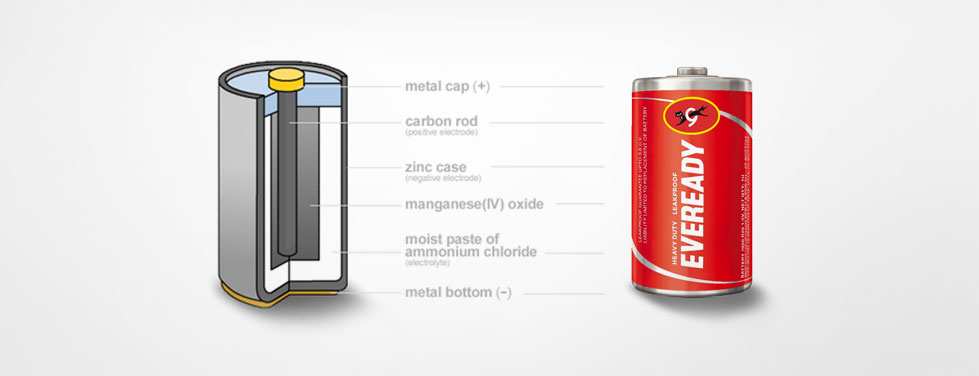

This modern laboratory is equipped to test Zinc Carbon Batteries, Alkaline Batteries, NiMH/NiCd Batteries, Lithium Cells, Lead Acid Batteries, and Button Cells in accordance with Indian and International standards. It strengthens the organisation’s position as a market leader by developing commercially viable products and fostering innovation in environment-friendly solutions, including the recycling of hazardous waste.

Manufacturing of a dry cell battery, a ready portable source of energy, requires robust research and development to ensure standardisation and determine suitability.

Did you know that at Eveready, we manufacture dry cell batteries using 30 to 35 raw materials? Each of these raw materials undergoes 315 to 320 physico-chemical property checks for compliance before the actual manufacturing process begins!

During manufacturing, 110 to 120 process parameters are verified, and 100% compliance is ensured before a dry cell battery is produced.

All Eveready cells undergo voltage and amperage testing to ensure no defective cells enter the market.

Such stringent processes and parameter checks require vast data information and processing capability. Our R&D Centre is at the forefront, working tirelessly to meet all customer needs through new developments, design and artwork modifications, rigorous physical and chemical specification checks, and strict quality audits.

Rigorous Testing: All Eveready lighting models are tested as a part of the product development process. Testing includes performance testing, reliability testing and material testing as per the highest national and international standards.

Testing of market samples is also conducted for performance analysis and benchmarking.